ABOUT

US

Aibang Machinery Technology Co., Ltd. is a Chinese manufacturer of continuous rotary extrusion lines for copper and aluminum products. These production lines are available with different specifications and can produce yields such as the aluminum tube, copper flat wire, soft aluminum section wire, and the copper busbar and profile. Also available are continuous rotary extrusion equipment for producing aluminum clad steel wires.

Specializing in the research of continuous extrusion and continuous coating technology and the production of series of complete sets of equipment

Always take customer satisfaction service as the purpose, innovate customer life with taste, achieve customer satisfaction, and create higher value for customers

Possess a complete set of advanced test equipment and large-scale processing equipment, and has the ability to independently develop and manufacture core components

Products are exported to the United States, Japan, Germany, Italy, Turkey, India, France, Singapore, Indonesia, Pakistan and other countries

PRODUCTS CENTER

It has the advantages of high product quality, simple process, high efficiency, energy saving, and environmental protection

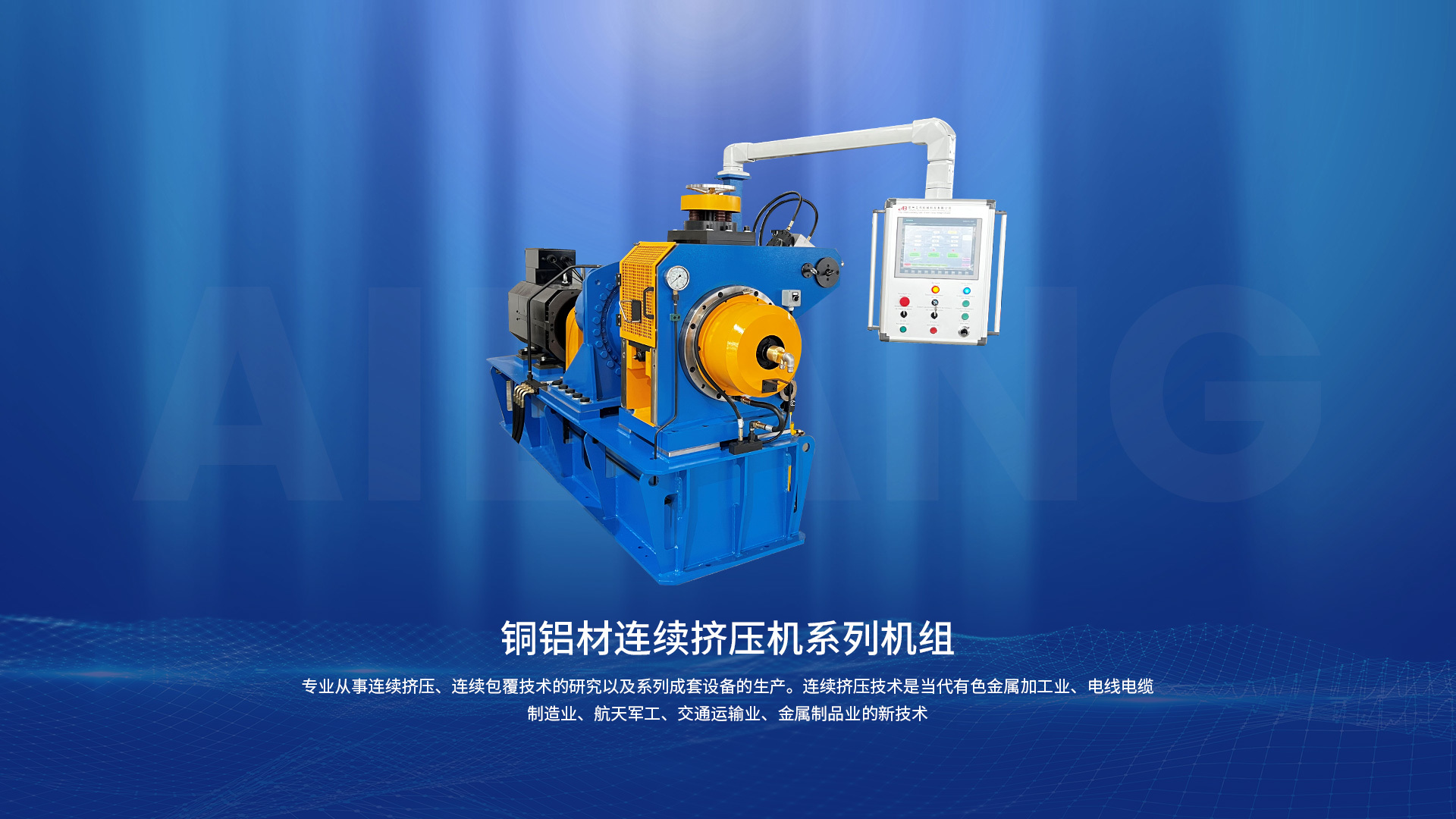

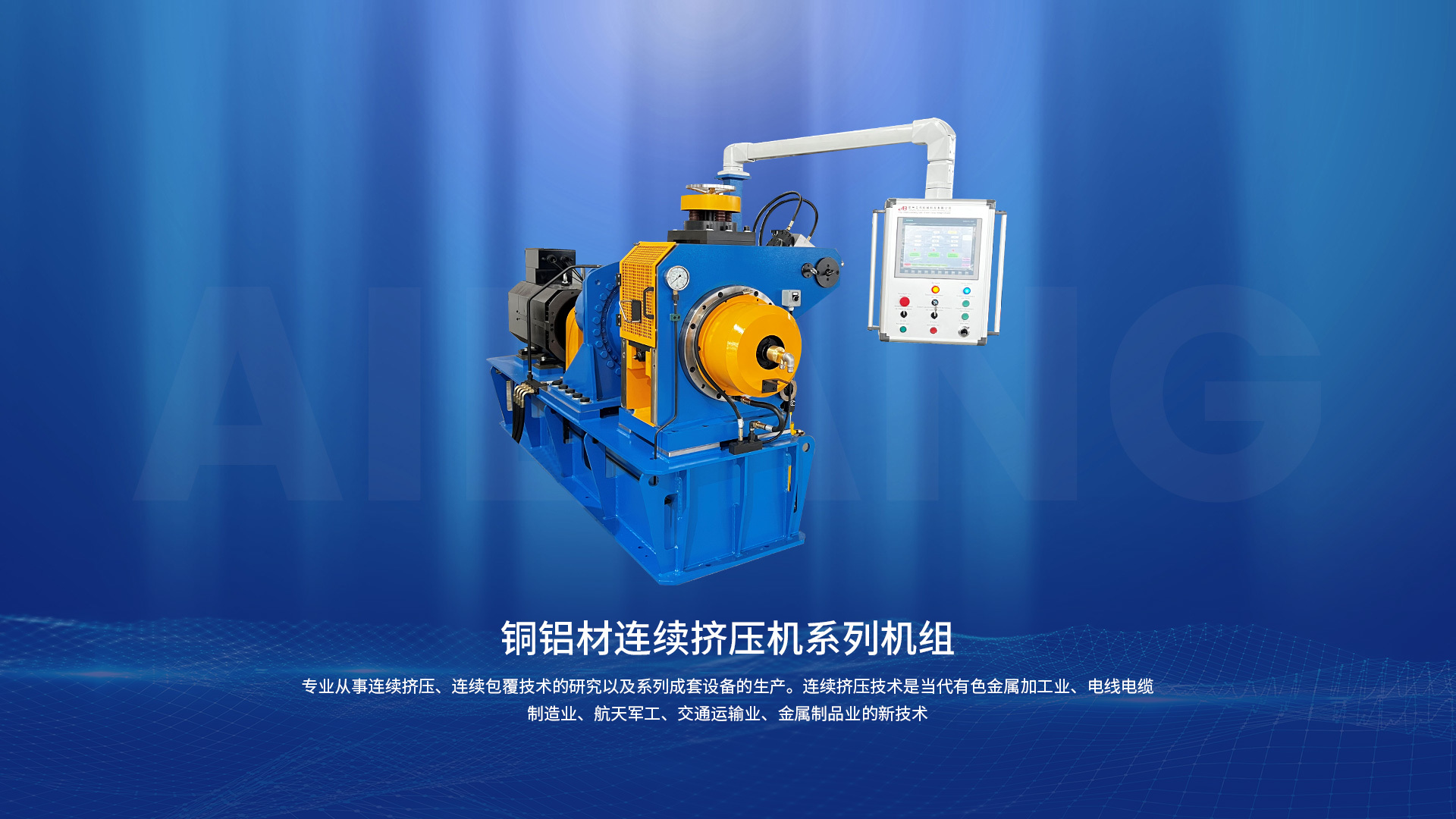

Copper and aluminum continuous extruder series unit

Continuous extrusion technology is a new technology in contemporary non-ferrous metal processing industry, wire and cable manufacturing, aerospace and military industry, transportation industry, and metal products industry.

Quality

Process

Energy saving

Environmental

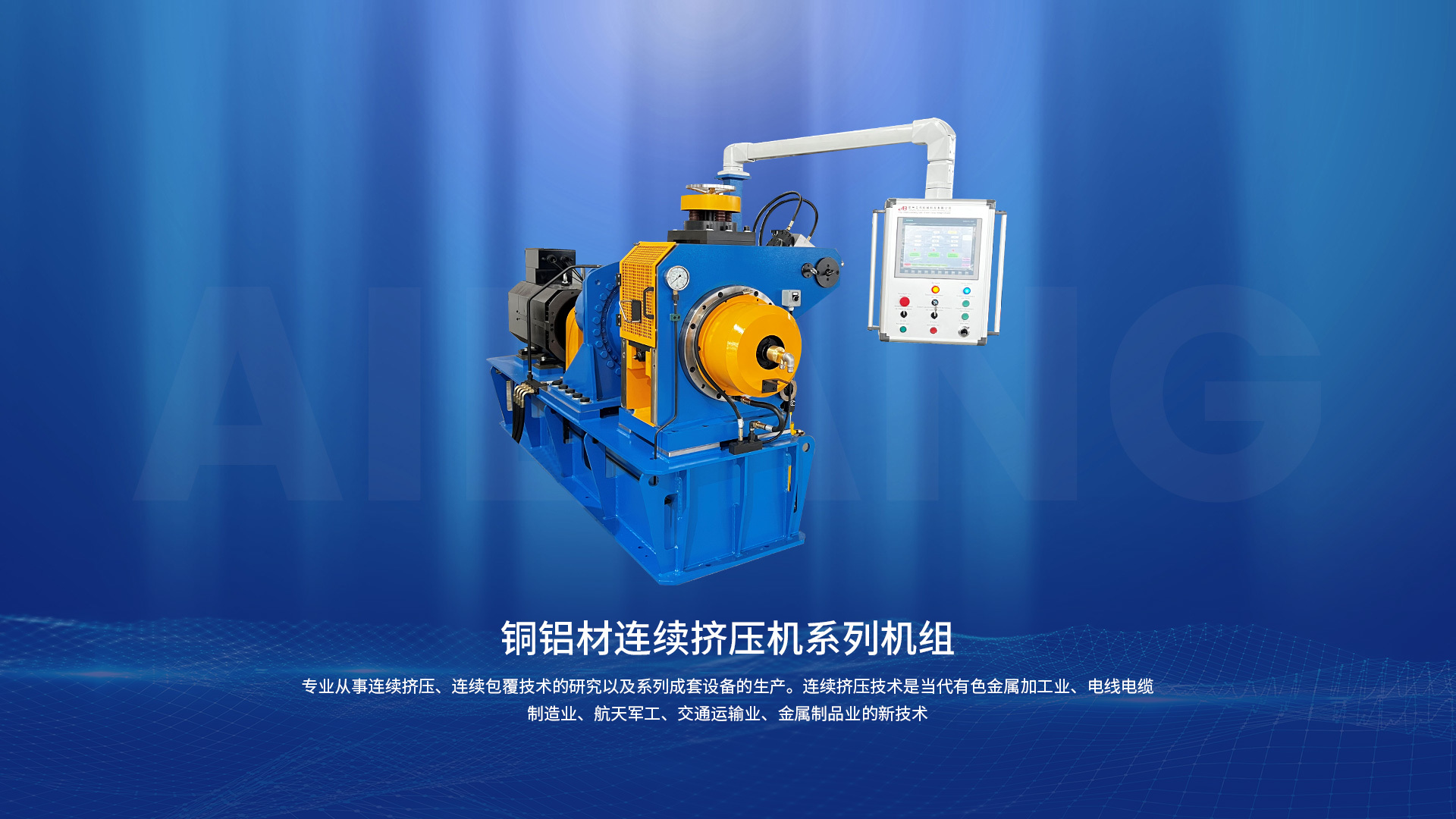

Copper and aluminum continuous extruder series unit

Continuous extrusion technology is a new technology in contemporary non-ferrous metal processing industry, wire and cable manufacturing, aerospace and military industry, transportation industry, and metal products industry.

Quality

Process

Energy saving

Environmental

Development and Application of Continuous Extrusion Technology

Continuous extrusion technology, as a new high-efficiency and environmentally friendly non-ferrous metal forming technology, has been widely concerned by research and application fields at home and abroad since its birth. This article introduces the working principle of continuous extrusion and its development, and gives a detailed description of the latest research results and progress in the field of continuous extrusion technology in our country, and summarizes the development trend of continuous extrusion technology at home and abroad in the future.

New Development of Extrusion Technology—Continuous Extrusion Method

Continuous extrusion technology is a new type of plastic pressure processing technology invented by the British in the 1970s and quickly promoted and applied in the 1980s. It is a new development and revolution to traditional extrusion technology. One, what is continuous extrusion As the name implies, the so-called continuous extrusion method is relative to the traditional extrusion process. The traditional extrusion process is a single intermittent production, and the continuous extrusion process can continuously supply blanks and continuously extrude products to achieve continuous production. Technology.

What is continuous extrusion technology?

Continuous extrusion: The die cavity is located on the side of the extrusion wheel, and the blank enters the extrusion cavity under the drive of the rotating extrusion wheel. Under the action of the friction force of the wheel groove, the temperature of the blank rises and the pressure increases. Extrude into the die hole to form a pipe or profile product. According to different types of equipment, the blank can be one or two; according to the different material of the blank, aluminum, copper and their alloys can be extruded. This working method is mainly used to produce refrigeration tubes for refrigerators, air conditioners, automobiles, special-shaped cross-section profiles, transformers, and copper magnet wires for motors.

ONLINE MESSAGE

在线留言

*注:请务必信息填写准确,并保持通讯畅通,我们会尽快与你取得联系

CONTACT

US

Aibang Machinery Technology Co., Ltd.

Add.: No. 279, Huanghe West Road, Xinbei District, Changzhou City, Jiangsu Province

Contact Person: Bangjun Shu

Phone: +86 13506124377

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible

copyright © 2023 Aibang Machinery Technology Co., Ltd.